As an environmental and manufacturing engineer, sound control and hearing protection has been a passion of mine for years. In fact, I even study it closely outside of my day gig (I'm a drummer)!

Excessive industrial noise can have harmful long-term effects on workers. “Industrial noise” refers to sound levels that exceed the reasonable range in the industrial work environment.

According to the U.S. Bureau of Labor Statistics (BLS), noise-induced hearing loss is one of the most common occupational illnesses, affecting about 30 million workers each year. Without measures to prevent industrial noise exposure, workers suffer. Here’s how to handle this hazard at your facility.

The Effects of Noise on Your Employees

Excessive noise in industrial business environments develop over long periods of time. Too often, facility managers and business owners ignore industrial noise because there are no visible effects of the damage it does. Failing to eliminate this hazard and protect employees has led to thousands of U.S. workers with permanent hearing damage and loss.

BLS data shows that hearing loss represents about 12% of reported occupational illnesses. This is equivalent to more than 18,000 workers with permanent hearing loss each year. Noise pollution can cause harms such as:

- Worker distraction, loss of concentration, and loss of productivity.

- Harm to short-term memory, reasoning, impulse control, and the ability to think clearly.

- Sleep disturbances, fatigue, irritability, anger, and psychological dysfunctions.

- Stress, migraines, high blood pressure, peptic ulcers, and coronary disease.

- Reduced white blood cell count and weakened immune system.

- Long-term hearing loss or ringing in the ears (tinnitus).

- Increased risk of occupational injury from inability to hear.

Harmful industrial noise (anything with sounds above 90 decibels) can stem from large trucks, jackhammers, jet engines, and other heavy machinery. The manufacturing industry has the highest rates of work-related hearing loss, followed by utilities and transportation/warehousing.

High noise levels over prolonged periods, and even ambient noise, can cause permanent hearing loss. Workers with hearing loss may not be able to communicate as effectively or hear warning signals and instructions. This puts their lives in danger in the industrial workplace.

The Hierarchy of Controls for Noise Reduction

Excessive noise in the industrial business environment can interfere with operational efficiency and cause permanent harm to your employees. The National Institute for Occupational Safety and Health (NIOSH) recommends a maximum noise level of 85 decibels for eight hours at a time for workers.

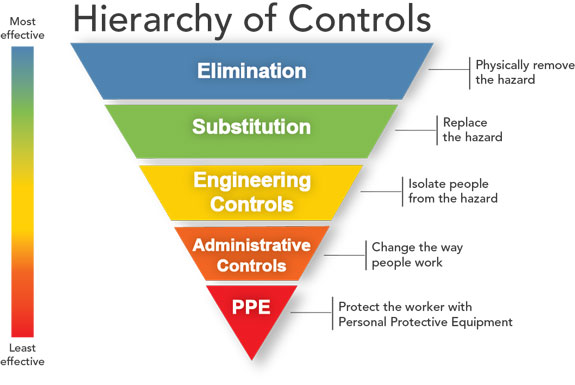

NIOSH encourages employers, employees, and occupational safety and health professionals to learn more about the dangers of noise exposure and to take steps to prevent worker harm from excessive noise. One such step is what NIOSH calls the “hierarchy of controls.” The hierarchy of controls is a pyramid chart that shows the most and least effective ways to control noise in the workplace.

The preferred solution on the hierarchy is Elimination, or the complete physical removal, of the excessive noise source. If this isn’t possible, the second-best solution is Substitution of the hazard. While this may be a simple solution for new processes, those environments with long-standing practices may find that a major shift is too time consuming or costly to implement.

On the bottom of the pyramid, and among the least effective, are Administrative Controls and PPE (personal protective effective). Compared to the other solutions, these options are the least expensive to establish, but require active participation from all parties and have the highest risk of harmful effects.

After reviewing the hierarchy of controls, many employers are often faced with either investing significant time and resources to create a safe work environment or run the risk of excessive noise pollution with less effective solutions. But, there is still one control to review.

Engineering Controls to Reduce Noise Pollution

Sometimes it’s not possible to eliminate the source of excessive industrial noise or replace it with something less hazardous. In these situations, facilities should use Engineering Controls to reduce noise pollution or remove the sources of the noise.

“Engineering controls” on the hierarchy refers to physical changes within the workplace. These can include installing physical noise-blocking barriers that prevent sound waves from reaching workers or that isolate noise sources in an insulated enclosure.

Putting up sound walls, windows, or other barriers to protect employees from sources of excessive noise can be an excellent solution for industrial noise control. It doesn’t require a total facility overhaul, yet still provides employees with ample noise protection. Because each facility has a unique set of needs, it’s best to consult with an engineer who has experience in noise control and industrial hygiene.

Our team is qualified and well-networked to assist with your noise control challenges. We'll devise a solution that keeps your employees happy, healthy, and productive.

Schedule a free consultation with BCX to discuss your business environment concerns, including noise control, air quality, and industrial hygiene.